| Item | 15-15 | 20-20 | 25-25 | 30-30 | 40-40 | 45-45 | 50-50 |

| Size | |||||||

| Tensile Strength KN/m(MD) ≥ | 15 | 20 | 25 | 30 | 40 | 45 | 50 |

| Tensile Strength KN/m(CD) ≥ | 15 | 20 | 25 | 30 | 40 | 45 | 50 |

| Elongation Rate%(MD) ≤ | 13 | ||||||

| Elongation Rate%(CD) ≤ | 13 | ||||||

| Tensile strength at 2% elongation KN/m(MD) ≥ | 5 | 7 | 9 | 10.5 | 14 | 16 | 17.5 |

| Tensile strength at 2% elongation KN/m(CD) ≥ | 5 | 7 | 9 | 10.5 | 14 | 16 | 17.5 |

| Tensile strength at 5% elongation KN/m(MD) ≥ | 7 | 14 | 17 | 21 | 28 | 32 | 35 |

| Tensile strength at 5% elongation KN/m(CD) ≥ | 7 | 14 | 17 | 21 | 28 | 32 | 35 |

| Junction Effciency % | 93 | ||||||

| Length (m) | 50 | ||||||

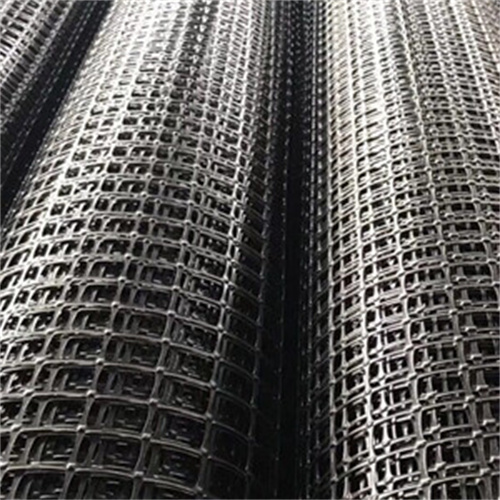

(1) firstly, the slope line of subgrade is accurately released. In order to ensure the width of subgrade, each side is widened by 0.5m. After the leveling of the base-soil, 25T vibratory roller is used for static pressure twice, and 50T vibratory pressure is used for four times. (2) lay 0.3m thick medium (coarse) sand. After manual and mechanical leveling, the vibration roller of 25T will be static pressed twice. (3) laying PP Biaxial Geogrid, PP Biaxial Geogrid laying floor should level off, dense, generally should be flat, straight, can not overlap, not curl, kink, the adjacent two geogrids to lap 0.2 m, and along the embankment lateral part of geogrid lap every 1 meter by using 8 wire connection, and the laying of the grille, 1.5 2 m with U every nail fixed on the floor. (4) after the first layer of PP Biaxial Geogrid is paved, the second layer of 0.2m thick medium (coarse) sand shall be filled in, with a total thickness of 0.5m.Four, eighty-two, eighty-two. One, seven seven. The methods: car to the construction site loaded with sand discharge in roadbed side, and then with a bulldozer driven push forward, put on both sides of subgrade filling after 0.1 m 2 m scope, fold the first layer geogrid flipping over again fill in 0.1 meters of coarse sand, ban on both sides to the middle of filling and propulsion, banned all kinds of machinery without filling sand (coarse) geogrid to traffic assignment, so that can guarantee smooth geogrid, don't drum, not wrinkle, stay in the second layer (coarse) after sand smooth, level measurement, prevent uneven filling thickness, after waiting for sight and correct for 25 t vibratory roller static pressure twice. (5) the construction method of the second layer of geotechnical grating is the same as that of the first layer, and the middle (coarse) sand of 0.3m is finally filled in. The filling method is the same as that of the first layer, and the static pressure of 25T roller is used for two times, so that the reinforcement of the subgrade base is completed. (6) in the third layer (thick) sand compaction, longitudinal in slope on each side along the route laying geogrid two paintings, lap 0.16 m, is connected by the same method, and then start earthwork construction, laying geogrid slope protection, must be measured on each floor laid side, each side to ensure the slope after renovation geogrids embedded analysis within 0.10 m. (7) each slope geogrid is filled with two layers of soil, that is, when the thickness is 0.8m, a layer of geogrid shall be laid on both sides at the same time, and then by the same method, until it is laid under the soil on the shoulder surface of the road. (8) after the subgrade is filled, the slope shall be repaired in a timely manner, and the foot of the slope shall be protected by dry masonry slabs. The subgrade shall be widened by 0.3m on each side and 1.5% settlement shall be reserved.

(1) firstly, the slope line of subgrade is accurately released. In order to ensure the width of subgrade, each side is widened by 0.5m. After the leveling of the base-soil, 25T vibratory roller is used for static pressure twice, and 50T vibratory pressure is used for four times. (2) lay 0.3m thick medium (coarse) sand. After manual and mechanical leveling, the vibration roller of 25T will be static pressed twice. (3) laying PP Biaxial Geogrid, PP Biaxial Geogrid laying floor should level off, dense, generally should be flat, straight, can not overlap, not curl, kink, the adjacent two geogrids to lap 0.2 m, and along the embankment lateral part of geogrid lap every 1 meter by using 8 wire connection, and the laying of the grille, 1.5 2 m with U every nail fixed on the floor. (4) after the first layer of PP Biaxial Geogrid is paved, the second layer of 0.2m thick medium (coarse) sand shall be filled in, with a total thickness of 0.5m.Four, eighty-two, eighty-two. One, seven seven. The methods: car to the construction site loaded with sand discharge in roadbed side, and then with a bulldozer driven push forward, put on both sides of subgrade filling after 0.1 m 2 m scope, fold the first layer geogrid flipping over again fill in 0.1 meters of coarse sand, ban on both sides to the middle of filling and propulsion, banned all kinds of machinery without filling sand (coarse) geogrid to traffic assignment, so that can guarantee smooth geogrid, don't drum, not wrinkle, stay in the second layer (coarse) after sand smooth, level measurement, prevent uneven filling thickness, after waiting for sight and correct for 25 t vibratory roller static pressure twice. (5) the construction method of the second layer of geotechnical grating is the same as that of the first layer, and the middle (coarse) sand of 0.3m is finally filled in. The filling method is the same as that of the first layer, and the static pressure of 25T roller is used for two times, so that the reinforcement of the subgrade base is completed. (6) in the third layer (thick) sand compaction, longitudinal in slope on each side along the route laying geogrid two paintings, lap 0.16 m, is connected by the same method, and then start earthwork construction, laying geogrid slope protection, must be measured on each floor laid side, each side to ensure the slope after renovation geogrids embedded analysis within 0.10 m. (7) each slope geogrid is filled with two layers of soil, that is, when the thickness is 0.8m, a layer of geogrid shall be laid on both sides at the same time, and then by the same method, until it is laid under the soil on the shoulder surface of the road. (8) after the subgrade is filled, the slope shall be repaired in a timely manner, and the foot of the slope shall be protected by dry masonry slabs. The subgrade shall be widened by 0.3m on each side and 1.5% settlement shall be reserved.| 1, Biaxial Geogrid can Improving bearing capacity of foundation |

| 2, Biaxial Geogrid can Prevent cracking and subsiding |

| 3, Biaxial Geogrid is Convenient to construct, reducing cost and maintaining expense |