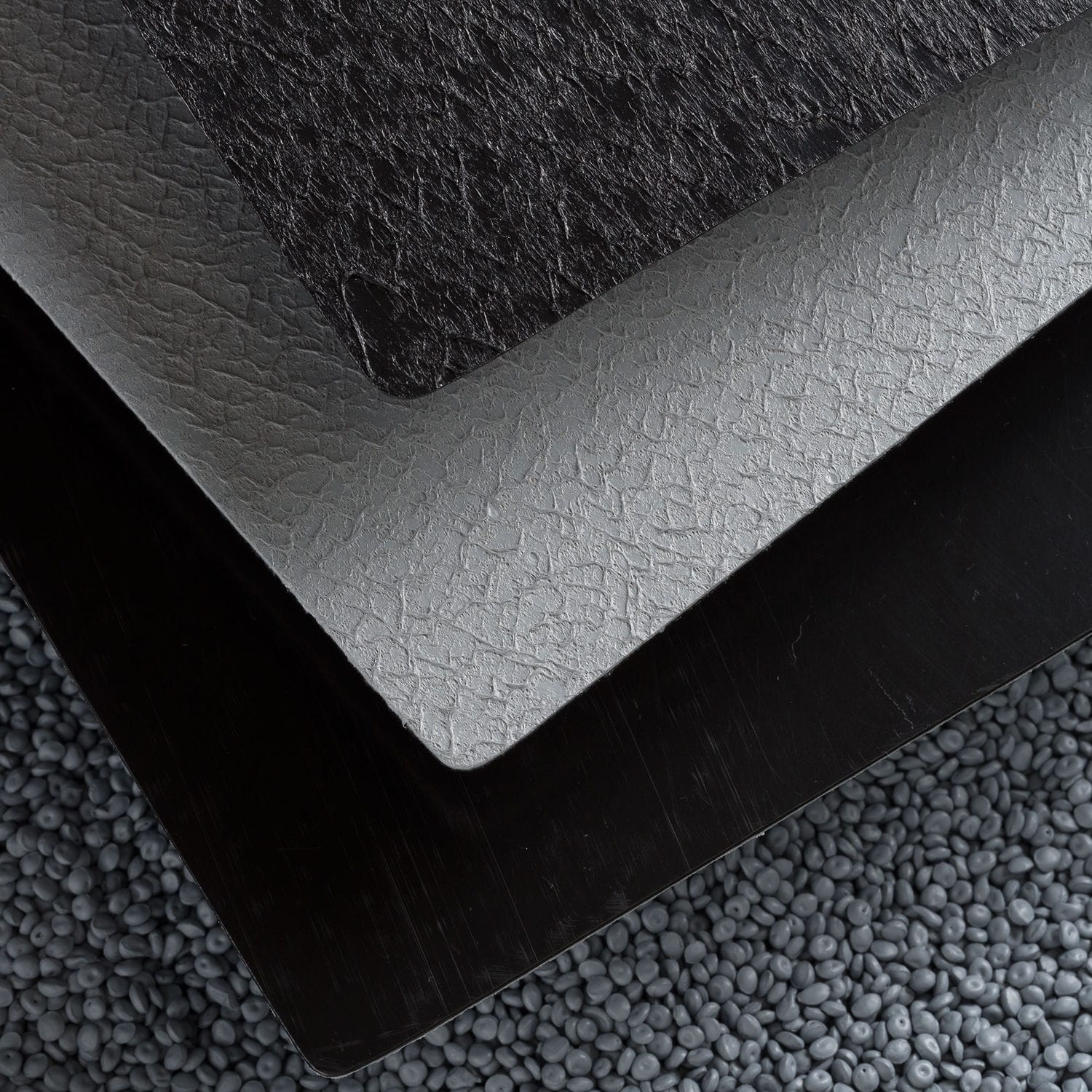

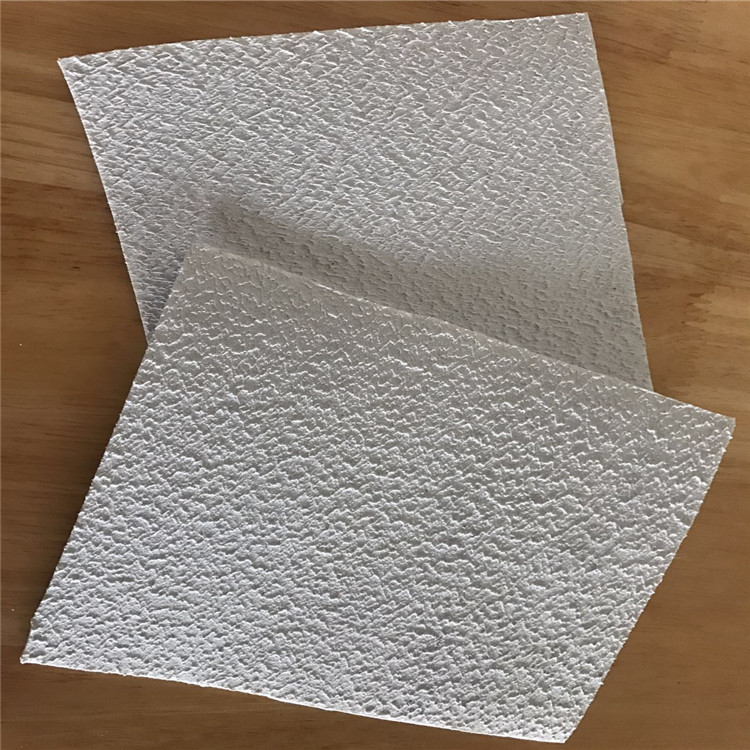

| Double textured HDPE Geomembrane | |||||||

| No. | Test item |

| |||||

| Thickness(mm) | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 | |

|

| Texture hegiht (mm) | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 |

| 1 | Density g/m2 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 |

| 2 | Tensile Yield Strength (MD&TD) (N/mm) | ≥15 | ≥18 | ≥22 | ≥29 | ≥37 | ≥44 |

| 3 | Tensile Breaking Strength (MD&TD) (N/mm) | ≥10 | ≥13 | ≥16 | ≥21 | ≥26 | ≥32 |

| 4 | Elongation at yield (MD&TD) (%) | 12 | |||||

| 5 | Elongation at break(MD&TD) (%) | 100 | |||||

| 6 | Tear Resistance (MD&TD) (N) | ≥125 | ≥156 | ≥187 | ≥249 | ≥311 | ≥374 |

| 7 | Puncture Strength (N) | ≥267 | ≥333 | ≥400 | ≥534 | ≥667 | ≥800 |

| 8 | Tensile load stress cracking (Constant load tensile method of incision) h | 300 | |||||

| 9 | Carbon Black Content (%) | 2.0-3.0 | |||||

| 11 | Oxidative Induction Time (min) | Atmospheric oxidative induction time≧100 | |||||

| High pressure oxidative induction time≧400 | |||||||

| 12 | 85°C heat aging (Atmospheric OIT retention after 90d) (%) | 55% | |||||

| 13 | UV protection (OIT retention rate after 1600 h uviolizing) | 50% | |||||